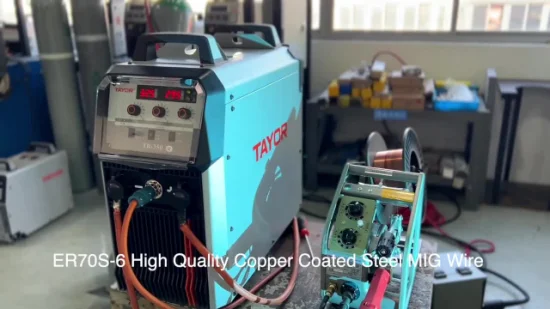

Mild Steel Copper Coated 0.8mm 1.0mm 1.2mm 1.6mm Sg2 Er70s

Overview Product Description Features: ER70S-6 is a kind of mild steel copper coated welding wire, suitable for 100% CO2

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | ER70S-6 |

Product Description

Product Description

Features:

ER70S-6 is a kind of mild steel copper coated welding wire, suitable for 100% CO2 and Argon& CO2 mixed gas protective welding with stable feasibility, good welding seams, less spatters and excellent welding process properties.

Application:

Used to weld ship building steel(A,B,D,E,A36,D36,E36)and equivalent mild steel or 550Mpa grade mild alloy steel, such as container building, construction machine, railway construction, pressure vessel for semi-auto or automatic gas shielded welding.

Conform with:

GB/T: ER50-6 DIN: SG2 JIS: YGW12

AWS: ER70S-6 BS: A18 EN: G3Sil

| Package | ||

| Specification | Wire Tray | Weight |

| Φ0.8~1.6mm | D100mm D200mm D270mm D300mm K300mm | 1kg, 5kg, 15kg, 17kg, 18kg, 20kg |

| Wire Chemical Composition(%) | |||||||

| C | Mn | Si | P | S | Cr | Ni | Cu |

| 0.06~0.15 | 1.40~1.85 | 0.80~1.15 | ≤0.025 | ≤0.035 | - | - | ≤0.50 |

| Deposited Metal Mechanical Properties | |||

Yield Strength σ0.2(Mpa) | Tensile Strength σb(Mpa) | Elongation δ5% | AKV Impact Energy (J)(-40ºC) |

| ≥420 | ≥500 | ≥22 | ≥90 |

| Diameter of Wire(mm) | Φ0.8 | Φ1.0 | Φ1.2 | Φ1.6 |

| Welding Current(A) | 40~140 | 50~220 | 80~350 | 120~450 |

| Matters needing attention: |

1. Wire into the plant must be stored in dry conditions, can not open welding wire coil waterproof packaging. 2. Welding shall be removed before welding surface oil, rust, water and other impurities. 3. The CO2 gas protection, CO2 gas purity 99.98%. 4. CO2 welding protective gas flow rate should be controlled at 20~25L/min. 5. Wire extension length should be controlled in the range of 15~25mm. |

Outer Packing: 1 spool/ctn (Every spool product is strongly packed by carton box with antirust paper inside.)

Container Load: 72boxes/pallet, 60boxes/pallet, 22pallets/20ftCompany Profile